G

Guest

Guest

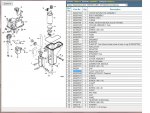

I have a 2006 60 EFI 4 stroke bigfoot. It starts and runs like new, but when I shut the motor off it drips fuel out of the overflow from the vapor separator tank until pressure is off the system. From diagrams I have looked at this is probably due to a float sticking or maybe some debris in the VRT. How easy is this to clean out or should I take it to a dealer? I think a replacement VST is about $700. What might a dealer charge to clean this out or would they more than likely just change it out?