templeguru

Cadet

- Joined

- Apr 6, 2017

- Messages

- 7

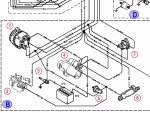

Greetings...my first post as a newbie so your patience is appreciated. I'm trying to help a friend get his boat going and the problem seems to be fuel delivery. He replaced the fuel pump last season and got about 3hrs of boating before it quit. Based on the tests I've done, the fuel pump isn't getting power. the ignition has power, the boat will even run if I pour fuel down her throat and the pump works with direct power so?.. Is the fuel pump power circuit routed through the ECM? I don't want to misguide him towards a $200 part that is undamaged.

1999 Mercruiser 4.3L - S/N 0L620402

2BBL carb

ECM # 861251-1

The key "ON" position has a continuous tone rather than beeps. Also, perhaps unrelated but in the course of diagnosing the problem, it seems like the trim function has quit working as well.

Thanks for reading.

1999 Mercruiser 4.3L - S/N 0L620402

2BBL carb

ECM # 861251-1

The key "ON" position has a continuous tone rather than beeps. Also, perhaps unrelated but in the course of diagnosing the problem, it seems like the trim function has quit working as well.

Thanks for reading.