Chris Hays

Petty Officer 3rd Class

- Joined

- Aug 14, 2007

- Messages

- 87

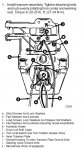

First off i want to say what a wealth of information this site is, ive been looking for hours on here!! I am in the process, (albeit rather slow), of rebuilding a 1990 Glastron Sierra 175 with a Mercruiser 3.0l and Alpha 1 outdrive. I have replaced the floor and its now time to mount the gimbal housing and inner transom plate back up to the transom. I have ordered all new hardware to bolt it back up but have a couple of questions.

1/ Do i just mount the gimbal housing to the transom dry, or add some kind of sealer to the seal?? (It looks like the seal was glued to the housing but not the transom).

2/ How tight do all the bolts need to be between the gimbal and tran. plate?

3/ Is it easier to replace the gimbal bearing with the housing mounted to the boat or off wrestling it around the garage?? lol.

4/ Could i use my original output shaft as an engine alignment tool or do i need to fork out for the real jobby??

5/ I replaced the wooden beam, or lateral stringer??, where the front engine mount, mounts too. When mounting do i drill holes and use bolts and nuts or can i use lag bolts??

6/ When i get to mounting items like my battery tray and seats, what is the best practice for sealing the screw holes i will be 'reluctantly' putting in my brand new floor?

Sorry for all the questions but i am needing EXPERT advice and im sure ill find it here!!

Thanks

(Also, i am a heavy equipment specialist by trade so any questions on Diesel engines, electrics or hydraulics feel free to shoot me a message)

1/ Do i just mount the gimbal housing to the transom dry, or add some kind of sealer to the seal?? (It looks like the seal was glued to the housing but not the transom).

2/ How tight do all the bolts need to be between the gimbal and tran. plate?

3/ Is it easier to replace the gimbal bearing with the housing mounted to the boat or off wrestling it around the garage?? lol.

4/ Could i use my original output shaft as an engine alignment tool or do i need to fork out for the real jobby??

5/ I replaced the wooden beam, or lateral stringer??, where the front engine mount, mounts too. When mounting do i drill holes and use bolts and nuts or can i use lag bolts??

6/ When i get to mounting items like my battery tray and seats, what is the best practice for sealing the screw holes i will be 'reluctantly' putting in my brand new floor?

Sorry for all the questions but i am needing EXPERT advice and im sure ill find it here!!

Thanks

(Also, i am a heavy equipment specialist by trade so any questions on Diesel engines, electrics or hydraulics feel free to shoot me a message)