JC612000

Seaman Apprentice

- Joined

- Mar 14, 2014

- Messages

- 34

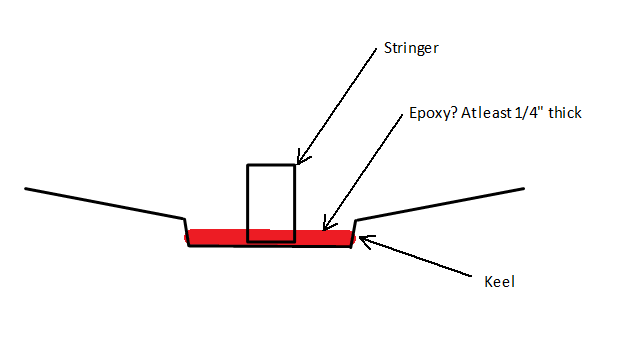

I've been lurking on this forum for a while now, and decided to start a thread. It may be long, or very short, but anyways, I haven't seen much discussion on any type of resto of a fish and ski. This boat was my grandfather's who passed away last year. I purchased it along with the trailer and motor for $500 from his estate. I've never owned a boat bigger than a conoe, but love being out on the water and love to fish as well. It has not been in the water for a long time.....probably 10+ years. It was full of water when I got it, so everything is rotted of course. I've spent only one day so far and that was dedicated to deconstruction. I plan on ripping the rest out in the near future and coming up with the game plan, that I was hoping to get some advice on. Anyway, I'll try and add a few pics to show you what I'm working with. Looks like floor replacement, possibly stringers as well and transom fix.

.

.