ttownthomas

Petty Officer 1st Class

- Joined

- Jun 7, 2019

- Messages

- 204

I am restoring a 1972 Bertram 25 with twin Mercruiser 165 L6's. I recently ran all new fuel plumbing from the tank to the engines and removed the mechanical steering and replaced with hydraulic (mostly done). Replaced old trim pumps with alpha pumps and relocated them into a forward area and have removed or repaired a bunch of wiring in the engine compartment and helm area. Here are some pics of the engine and battery wells:

I finally got around to running her again today after all the work got completed and I can't get the Stbd engine to stay running. I was back there and in the helm area monkeying around for about 2 months on and off getting this work done and I am thinking I may have knocked something loose in the electrical system.

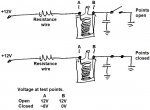

The engine turns over and fires when the ignition key is turned to start but seems to be running slightly too high of an rpm but when the key returns to the on position the engine dies right away.

During the survey this engine also had an issue "finding neutral" and I wonder if that and this may be related to the shift interrupt system?

I did check to make sure I have fuel at the carb so it is definitely an electrical related problem...

Any pointers?

I finally got around to running her again today after all the work got completed and I can't get the Stbd engine to stay running. I was back there and in the helm area monkeying around for about 2 months on and off getting this work done and I am thinking I may have knocked something loose in the electrical system.

The engine turns over and fires when the ignition key is turned to start but seems to be running slightly too high of an rpm but when the key returns to the on position the engine dies right away.

During the survey this engine also had an issue "finding neutral" and I wonder if that and this may be related to the shift interrupt system?

I did check to make sure I have fuel at the carb so it is definitely an electrical related problem...

Any pointers?