Darol Wester

Petty Officer 2nd Class

- Joined

- Nov 4, 2005

- Messages

- 157

Having run our boat (Mercruiser 350) in the salt 95% of the time we started removing and cleaning the risers every year. We've been scrapping and soaking them in muriatic acid then rinsing. It's a pain but it does the trick. For those that frequent the salt, how are you dealing with this problem, if it is one? Any tricks we should know about?

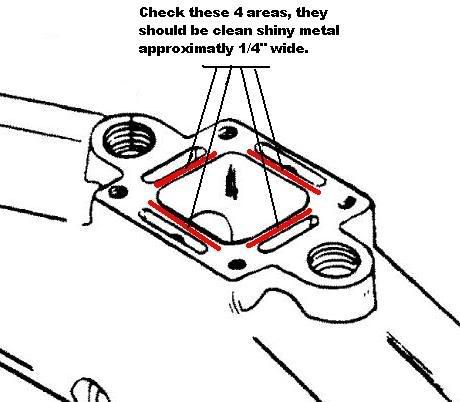

Also, no matter what gaskets we use at the riser/manifold, there's always leakage to some degree. We've tried the factory gaskets and have made some of our own and used a sealant, but can't seem to get a good seal. Is it possible? We have followed all the torque specs.

Also, no matter what gaskets we use at the riser/manifold, there's always leakage to some degree. We've tried the factory gaskets and have made some of our own and used a sealant, but can't seem to get a good seal. Is it possible? We have followed all the torque specs.