Hi Everyone,

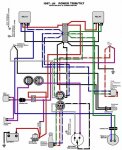

I'm new to this forum and have some questions about adding a power tilt and trim to my 1979 70hp Evinrude. Anyway, I've already purchased a used power tilt and trim unit. It has 2 wires coming from the motor, 1 blue and 1 green. So far, it appears that polarity is reversed to extend and retract. Initially, the business from where I purchased it from told me that one wire was up, the other was down and that it was grounded through its body. That didn't work, so I began checking with a volt-ohm meter and found no continuity between body and either wire, but found continuity through the wires only. up/down works by reversing polarity. If I'm doing something incorrect, stop me. Anyway, I'll begin today to install the power tilt and trim unit. From reviewing schematics, there appears to be parts which I may still need. Two of these are the thrust pads. I'm not 100% certain that I need them, but from what I call recall from some of my engineering classes, I believe they're needed to keep the forces from the engine, running parallel with the trim rods. The way I view it, I believe the thrust pads may be concave (schematic doesn't show that great of detail) for the trim rods to set into them. The person who sold this unit to me told me the power tilt and trim unit would just push on the existing bolts that are currently in place in the "swivel bracket (BRP Parts Listing). Currently there two brackets with springs attached to it which is part of the manual tilt mechanism. From what I see, these will be removed permanently along with several other parts in order install the power tilt and trim unit. Can the motor be run without these thrust pads and not damage the trim rods?

Next question, at this time I have no trim sender or gauge. Again I was told these aren't necessary could run the motor and just list for the pump to change tones. I realize that if the pump isn't shut off at full retract or full extend, that that could cause internal damage to the pump. It's probably like our power steering systems on our automobiles where the fluid superheats in the pump because there is nowhere to go. Also, does the trim sender have a limit that prevents you from trying to trim the motor to high (the point where tilt cylinder takes over). Any information anyone can give me to validate my thoughts would be greatly appreciated.

Steve

I'm new to this forum and have some questions about adding a power tilt and trim to my 1979 70hp Evinrude. Anyway, I've already purchased a used power tilt and trim unit. It has 2 wires coming from the motor, 1 blue and 1 green. So far, it appears that polarity is reversed to extend and retract. Initially, the business from where I purchased it from told me that one wire was up, the other was down and that it was grounded through its body. That didn't work, so I began checking with a volt-ohm meter and found no continuity between body and either wire, but found continuity through the wires only. up/down works by reversing polarity. If I'm doing something incorrect, stop me. Anyway, I'll begin today to install the power tilt and trim unit. From reviewing schematics, there appears to be parts which I may still need. Two of these are the thrust pads. I'm not 100% certain that I need them, but from what I call recall from some of my engineering classes, I believe they're needed to keep the forces from the engine, running parallel with the trim rods. The way I view it, I believe the thrust pads may be concave (schematic doesn't show that great of detail) for the trim rods to set into them. The person who sold this unit to me told me the power tilt and trim unit would just push on the existing bolts that are currently in place in the "swivel bracket (BRP Parts Listing). Currently there two brackets with springs attached to it which is part of the manual tilt mechanism. From what I see, these will be removed permanently along with several other parts in order install the power tilt and trim unit. Can the motor be run without these thrust pads and not damage the trim rods?

Next question, at this time I have no trim sender or gauge. Again I was told these aren't necessary could run the motor and just list for the pump to change tones. I realize that if the pump isn't shut off at full retract or full extend, that that could cause internal damage to the pump. It's probably like our power steering systems on our automobiles where the fluid superheats in the pump because there is nowhere to go. Also, does the trim sender have a limit that prevents you from trying to trim the motor to high (the point where tilt cylinder takes over). Any information anyone can give me to validate my thoughts would be greatly appreciated.

Steve