fmt2bx

Petty Officer 1st Class

- Joined

- May 27, 2015

- Messages

- 217

Update 07/17/15

Today I was able to get the time to do the timing light check, here are the results:

#1,#3,#4 ok , #2 had no spark.

-swap plugs, #2 no spark.

-Swap coil #2 still no spark

- Swap CD boxes and #2 still no spark!!!

PS: during each test, #1, #3, #4 checked ok.

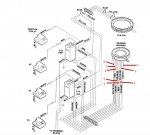

So from my limited experience and reading of the manual, it looks like the problem would come from the Trigger (?). I try to inspect the plugs of the CD boxes but I can't see anything wrong with them, if there is a faulty pin in there I can't tell, there isn't any corrosion or obvious problem. Also re-checked all the wires under the protective sleeve and same, all looked ok.

So if trigger it is, I have to remove the flywheel and I wanted to know if it was something that required lots of tuning afterwards or just remove and replace deffective part?

Also, where could I find the flywheel extractor tool? Should I change the Stator as well?

A quick search of this forum showed that triggers and stators are available, still need to find out which model is the correct one for the motor.

I also check for fuel blowback earlier and I couldn't see anything noticeable, here is the video (note: turned out to be on 3 cylinders only).

https://youtu.be/N6y86ulpxwI

At least with all of your guys help I was able to go this far. Hopefully, I can fix this.

Thank you all so much for your help.

Cheers

FMT

Today I was able to get the time to do the timing light check, here are the results:

#1,#3,#4 ok , #2 had no spark.

-swap plugs, #2 no spark.

-Swap coil #2 still no spark

- Swap CD boxes and #2 still no spark!!!

PS: during each test, #1, #3, #4 checked ok.

So from my limited experience and reading of the manual, it looks like the problem would come from the Trigger (?). I try to inspect the plugs of the CD boxes but I can't see anything wrong with them, if there is a faulty pin in there I can't tell, there isn't any corrosion or obvious problem. Also re-checked all the wires under the protective sleeve and same, all looked ok.

So if trigger it is, I have to remove the flywheel and I wanted to know if it was something that required lots of tuning afterwards or just remove and replace deffective part?

Also, where could I find the flywheel extractor tool? Should I change the Stator as well?

A quick search of this forum showed that triggers and stators are available, still need to find out which model is the correct one for the motor.

I also check for fuel blowback earlier and I couldn't see anything noticeable, here is the video (note: turned out to be on 3 cylinders only).

https://youtu.be/N6y86ulpxwI

At least with all of your guys help I was able to go this far. Hopefully, I can fix this.

Thank you all so much for your help.

Cheers

FMT