I'm just about to fit a helicoil thread insert to a hole where a sheared cylinder head bolt has been removed.

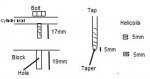

The hole has been filled so I need drill the hole and I'm trying to work out what the depth of the hole needs to be, and am not sure how far into a hole you can wind a helicoil. I've depicted it here:

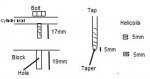

The last 5mm of the tap is tapered, so I'm assuming that I won't be able to wind in the helicoil this last 5mm. Is this right? Assuming the head gasket is about 1mm thick, the bolt will extend 16mm into the hole. But if I can't use that last 5mm, the threaded part of the hole can only really be 14mm. I'm assuming I'll need to use a shorter bolt and 2 helicoils.

Is this right or can I wind the helicoil in that last 5mm?

The hole has been filled so I need drill the hole and I'm trying to work out what the depth of the hole needs to be, and am not sure how far into a hole you can wind a helicoil. I've depicted it here:

The last 5mm of the tap is tapered, so I'm assuming that I won't be able to wind in the helicoil this last 5mm. Is this right? Assuming the head gasket is about 1mm thick, the bolt will extend 16mm into the hole. But if I can't use that last 5mm, the threaded part of the hole can only really be 14mm. I'm assuming I'll need to use a shorter bolt and 2 helicoils.

Is this right or can I wind the helicoil in that last 5mm?