StingrayMike

Petty Officer 1st Class

- Joined

- Aug 17, 2014

- Messages

- 355

Been around for abit, i have gotten alot of good info, but now i need some help.

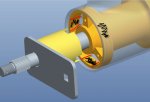

my shaft oil seal is leaking, but i cannot remove the shaft housing, my local volvo mechanic has never taken one off, and does not know what tool to use.

he recomended cutting a pipe and put some nipples on it.

if so what do i turn it? Is it reverse threaded?

thanks

my shaft oil seal is leaking, but i cannot remove the shaft housing, my local volvo mechanic has never taken one off, and does not know what tool to use.

he recomended cutting a pipe and put some nipples on it.

if so what do i turn it? Is it reverse threaded?

thanks