- Joined

- Jul 23, 2011

- Messages

- 52,062

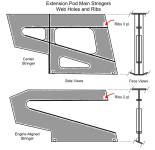

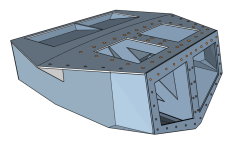

will look on a model of an aluminum pod for the rigging tubes. may be tomorrow by the time I get the info

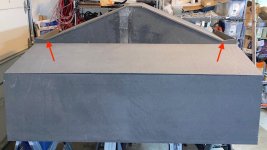

deck plate. how big is your arm near your shoulder. Armstrong has their own (doesnt use a mounting ring) and the ones with a mounting ring have a smaller opening.

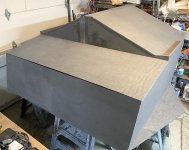

fiberglassing the inside - gravity is your friend. I suggest fiberglass the low flat surface wrapping a bit up each side, cure, turn the assembly 90 degrees, rinse and repeat I would do a good 1/4" or more on the inside (thicker at the joints)

openings in the bulkheads help with access.

deck plate. how big is your arm near your shoulder. Armstrong has their own (doesnt use a mounting ring) and the ones with a mounting ring have a smaller opening.

fiberglassing the inside - gravity is your friend. I suggest fiberglass the low flat surface wrapping a bit up each side, cure, turn the assembly 90 degrees, rinse and repeat I would do a good 1/4" or more on the inside (thicker at the joints)

openings in the bulkheads help with access.