Re: Inline 6 150hp Link&sync advice!

correct!! The last line in my previous post is wrong. I should of said ( Then you use your dial indicator and set your pointer to the 464 mark. Sorry about that!

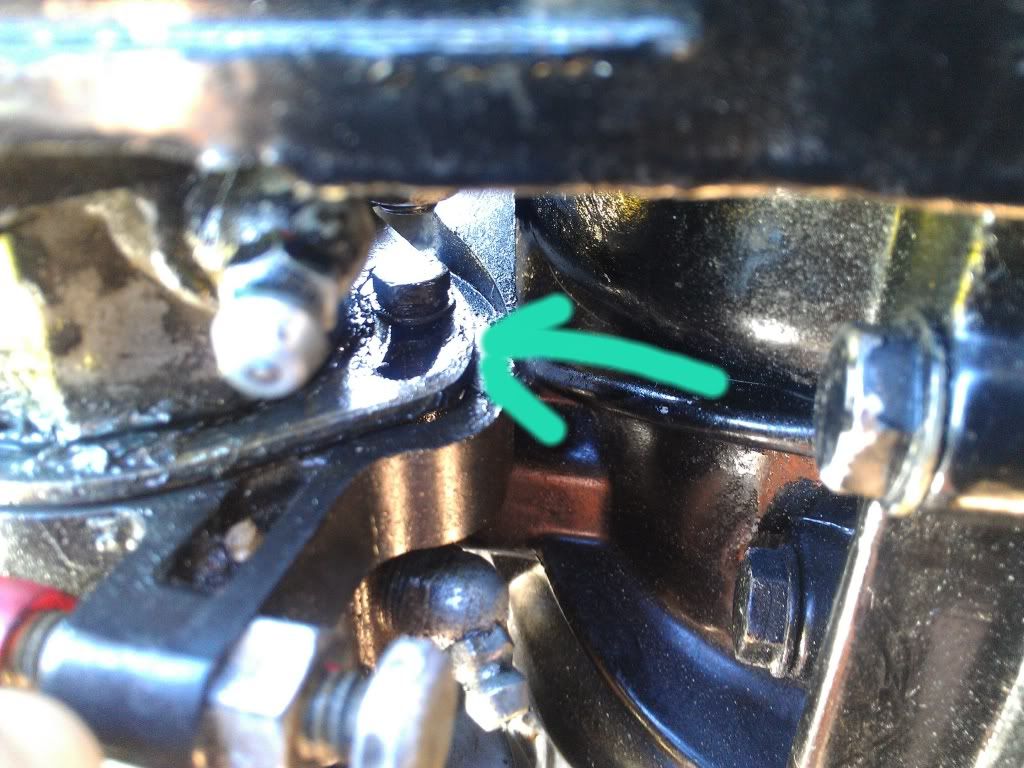

Yes the pointer on the distubertor , dots on the flywheel, and center of the crankshaft have always lined up when I have done a link and sync on them. If you line up every thing as it should be then the timming marks will show the TDC mark and pointer more adavanced that what is shown. The belt timming being off one tooth will also make a diffrence of where things should sync up . JMO

Oldman570

correct!! The last line in my previous post is wrong. I should of said ( Then you use your dial indicator and set your pointer to the 464 mark. Sorry about that!