Re: Install Trim Limit & Trim Senders

I am in total agreement with RB. If your a Tech, safety is your primary concern, as well as the liability issue. If you get sued, your done. If you have a paper trail with work done per the manuals and policies and procedures, you don't have anything to worry about. I have been an Aviation Engineer/Technican for almost 30 years and do everything by the book, as it should be done. I won't install a part unless it has a paper trail with a history back to the manufacturer. I don't lose any sleep at night worrying about an airframe that I have released for flight, thinking it may end up a "smoking hole" in the ground somewhere! You're work quality should not be dictated by who is looking over your shoulder. It is your personal dedication to knowing the work has been done correctly. If the customer wants to cut corners, thats his business and you shouldn't get involved. Period. I am a Craftsman by trade and very proud of the fact that my work speaks for itself. I'm off my soapbox. My hat is off to you RB!

I just fixed my trim system yesterday. I was fortunate that the trim interrupt for trim up is working correctly, per the manual. Can you bypass the circuit and get by, sure you can! When you burn up your engine due to weak cooling due to pump cavitation, you'll be kicking yourself for not spending the labor hours or rate to fix the system correctly the first time! There is a reason for $90.00 + per hour shop rates. It's rather inexpensive insurance knowing the work had been done correctly the first time. Mechanics/Technicians get a bad rap. They continually have to clean up messes left behind by the owner who never inspects his craft for pending maintenance issues, much less taking the tasks at hand himself!

Jet Wrench

Trim/Tilt work performed yesterday:

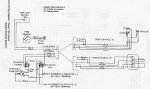

Thanks for the contributions to my trim issue. Good stuff on the forum to glean information from. I removed the trim motor and solenoid relays, cleaned and burnished all connections. Found that both relays had high resistance when latched when tested on the bench. I was able to disassemble both relays and clean/burnish the contacts (I'm a cheap SOB!, saved $40.00), they work great now. I removed the motor armature and brushes, burnished the armature and cleaned the housing. The brushes were in good shape, no issues. Easy to do, a little time consuming though. I lubricated shaft bushings and re-assembled the motor, tested on the bench, nice and smooth with good torque. These early motors are built very stout! It is fair to say they are much better quality than what you can buy new today. No plastic to get brittle and break. I was fortunate, the pump has nice clean fluid with no need to top off. I did replace the o-ring (packing) between the pump and motor assy's when going back together.

After re-assembly, turned on the master power and got nice linear up/down trim actuation from the thottle trim switch with good indication on the indicator and correct trim up operation with the skeg stopping at the right height before cavitation can occur. The trailer tilt operation worked correctly for up actuation, but did not work in down. Found the down wire from the switch was disconnected. The previous owner had worked on the wiring at some point and really FUBAR'ed the trim/tilt wiring at the instrument panel. I believe he tried to bypass the bad relay issue with no success and left it that way. I cleaned up his rat's nest and now have proper tilt/trim operation!

It ended up being four different issues:

BAD TRIM RELAYS

CORRODED TRIM MOTOR EXTERNAL TERMINALS

CORRODED TRIM MOTOR INTERNALS

COBBED WIRING

Thanks for your help with the diagrams.

JW