I am installing my outboard after reseal. When I go to put it onto the housing It keeps stopping 3/4" from flush. Being this far on I do not think it is the splines stopping it but I cannot figure out why it wont go on any further. I have the shifter in fwd however I am having a really hard time making the lever arm with the roller stay in between the pawls on the shifter piece. I think what may be happening is that the shifter arm is falling out of the moving piece and it is jamming and stopping me from installing the outboard any further. Is there anything I can do to make the arm stay inside the pawls where it is supposed to be? The last time I tried last night I ripped the gasket so we are going to be waiting until the new gasket comes in to try again.

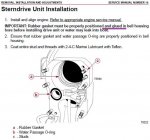

Side question, the big o ring that I am replacing that goes around the U joints. Am I supposed to be putting that into the outdrive housing where the stop for it is or am I supposed to be put it onto the outdrive itself?

Side question, the big o ring that I am replacing that goes around the U joints. Am I supposed to be putting that into the outdrive housing where the stop for it is or am I supposed to be put it onto the outdrive itself?