reelfishin

Captain

- Joined

- Mar 19, 2007

- Messages

- 3,050

I have an aluminum V hull which has a 15" transom, but most all of my motors are 20" shaft. The boat is only a 14.5" V hull with a minimal deadrise at the stern, maybe 4" or so.

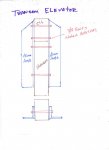

My question is, if I use a fixed jack plate, which raises the motor up, what is the correct setting or starting point? Most of the jack plates are 4" setback by 3.5" rise, making the measured height of my transom exactly 20". The boat has a max of 25 hp, and I have both a 25 and 10 hp motor which I'd like to switch back and forth as needed. Do I set the anti-cavitation plate as I would if the motor were directly on the transom?

Will I likely notice any adverse affects with the motor mounted on the plate?

I am guessing that I'll need to mount the plate at it's highest point to get the motor even with the bottom of the boat, and I think maybe it might need to be up a half inch or an inch which may be an issue. I use the same motors on another boat, so I don't want to convert them to 20" shafts and their perfect running motors as they are. (Usually if the 10hp is on this boat, the 25 hp is on my other boat or the opposite).

The boat is light, maybe 400lbs at best plus motor when in the water.

Is there any handling change or running characteristics associated with moving the motor back that little bit? Should I move it farther back? I can make my own jack plate if needed.

Anyone have any experience with a TH Mini Jacker?

http://www.iboats.com/T_H_Marine_Mi...14970563--**********.504744957--view_id.40133

I like the boat but would like to run my newer motors, which are all long shaft. I do have to say that I am a bit concerned about drilling the never drilled transom as well as the fact that the transom wood on this boat doesn't go to the bottom, so I will have to either only use the upper holes or add some sort of reinforcement to the lower transom?

My question is, if I use a fixed jack plate, which raises the motor up, what is the correct setting or starting point? Most of the jack plates are 4" setback by 3.5" rise, making the measured height of my transom exactly 20". The boat has a max of 25 hp, and I have both a 25 and 10 hp motor which I'd like to switch back and forth as needed. Do I set the anti-cavitation plate as I would if the motor were directly on the transom?

Will I likely notice any adverse affects with the motor mounted on the plate?

I am guessing that I'll need to mount the plate at it's highest point to get the motor even with the bottom of the boat, and I think maybe it might need to be up a half inch or an inch which may be an issue. I use the same motors on another boat, so I don't want to convert them to 20" shafts and their perfect running motors as they are. (Usually if the 10hp is on this boat, the 25 hp is on my other boat or the opposite).

The boat is light, maybe 400lbs at best plus motor when in the water.

Is there any handling change or running characteristics associated with moving the motor back that little bit? Should I move it farther back? I can make my own jack plate if needed.

Anyone have any experience with a TH Mini Jacker?

http://www.iboats.com/T_H_Marine_Mi...14970563--**********.504744957--view_id.40133

I like the boat but would like to run my newer motors, which are all long shaft. I do have to say that I am a bit concerned about drilling the never drilled transom as well as the fact that the transom wood on this boat doesn't go to the bottom, so I will have to either only use the upper holes or add some sort of reinforcement to the lower transom?