Re: Merc 700 points setting plate

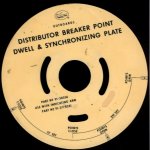

Attached is a scanned image of the 6-cyl dwell plate, just print & cut it out.

If you have an old busted or bad rotor, you can cut a hunk of wire, bend to suit and screw (or otherwise attach) the wire to the rotor, to serve as a makeshift pointer.

If you don't have that, just wrap a stout piece of wire around the dist. shaft and bend around so it's in the proper position to work as a pointer. OK for limited use, of course if you were doing these all the time you'd want to come up with something a bit easier to use.

Bore a hole in a hunk of wood the same size as the hole in the dwell plate; slip the plate over the distributor and plunk the whole mess down into the hole. Make sure the hole is loose enough so you can turn the distributor as needed. This makes a nice fixture to hold the dist in place while you're adjusting the timing.

Or cut a hole in a cardboard box & rest the distributor in that. Doesn't have to be fancy, just work!

BTW you'll be rotating the pointer/dist shaft CCW to make this adjustment. Which makes sense looking at the dwell plate.

Just remember the important thing about setting up one of these distributors is that the first set of points must have exactly 90 degrees of dwell (i.e. they must open 90 deg after they close); the second set of points must open 60 degrees after the first set opens, regardless of total dwell.

This ensures even firing between cylinders 1-3-5 and 2-4-6. Otherwise the uneven firing can cause vibration and has, in extreme cases, been known to break crankshafts. Tends to put a damper on things when that happens!

When set up right, these babies really purr. Enjoy the Silky-Smooth idle!

I had an old 700E DockBuster on a 13.5' Sea-King runabout back in the 80's and it was a great little rig, the motor never failed to impress the Wannabee's on the beach who were laughing at the old boat/motor until we hit the starter and roared away!!

HTH............ed