Great! You are getting gas to the carb!

But looks like the carb is

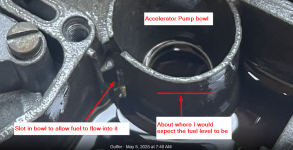

not filling up. The fuel level seems too low. See my blown-up picture of your picture. Note the Accelerator Pump bowl gets fed with the slot down the side of the bowl. I would expect the level to be somewhere around the line I drew.

So now it becomes a matter of why so low.

The float could be too heavy but that would cause it to overfill and flood out. So, I going to discount the float itself as the issue.

The float

adjustment could be an issue. When you rebuilt the carb, the kit should have a carboard measuring tool or some why to know the adjustment is correct. This involves holding the top of the carb upside down with the float attached and measuring between the top (or bottom) of the float and the bottom of the carb as indicated in the kit instructions. See this

link for some pictures and how to.

Another potential issue is the needle and seat being clogged or somehow not letting fuel in. You should be able to remove the entire needle & seat and pull out the needle and inspect the whole arrangement. Needle should move smoothly in and out of the seat and when you use your mouth to blow into the seat (where the gas would come in) it should unseat the needle and allow air flow. Keep your finger lightly over the needle and work it back and forth a few times (i.e. needle gets blowen out just a bit against your finger and you use your finger to push back in).

Another potential issue is a built-in filter in the carb that is clogged up. I think you checked this already, but best to double check.

Let us know.