drewpster

Commander

- Joined

- Oct 17, 2006

- Messages

- 2,059

Re: My tri-hull transom replacement w/ pics

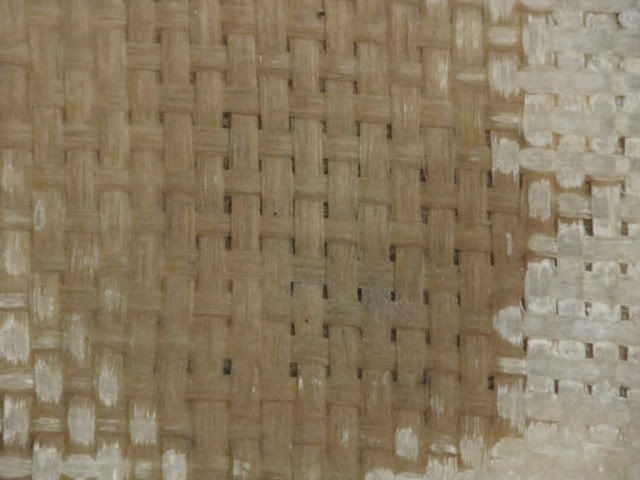

I have been without a camera for awhile but now I am back in business. The tri-hull is going well at this point. I have a good start on all the bottom repairs. I also completed a hull platform to keep the hull from getting out of shape.

I built it out of ply and 2x6. It took a long time to shape all those supports.

Once the hull gets flipped back over the form will include side bracing to support the sides. I will leave the hull in the form until the transom, stringers and deck get glassed back in.

I have been without a camera for awhile but now I am back in business. The tri-hull is going well at this point. I have a good start on all the bottom repairs. I also completed a hull platform to keep the hull from getting out of shape.

I built it out of ply and 2x6. It took a long time to shape all those supports.

Once the hull gets flipped back over the form will include side bracing to support the sides. I will leave the hull in the form until the transom, stringers and deck get glassed back in.