Looks like Boatinfo is down. Has happened before. They may come back, they may not...

Ok, trim systems 101...

First up, need to know which system you have. There's been a lot over the years...

How many solenoids (1 or 2)?

Is the pump motor round or square?

Is the reservoir metal or plastic?

Where is your shift plate (engine mounted or up against the inside of the transom)?

Do you have a reverse lock valve?

Trim control panel or buttons? (panel mounted or control box handle mounted)

So, some of the basics.

The trim pump motor is bi-directional. To pump UP, the motor spins one way, to pump DOWN, the motor spins the other way. 3 wires (about 6mm) run into the motor, a blue (for UP), and green (for DOWN) and the black ground. Easy way to remember, blue sky above you (UP), green grass below you (DOWN)...

UP pressure is higher than DOWN pressure, usually about double. And be warned, these are high pressures we are playing with. Treat them with respect! The UP side of the ram piston is full face, so you get maximum force. The DOWN side has the piston rod on it, so it has less force for a give pressure, and it has less pressure... One common problem we see on trim systems is the drive won't go down, even with oil in the pump and the pump running. Most of the time this is a corroded ram end cap. The corrosion puts a clamping force on the piston rod and the force generated by the pump isn't enough to overcome it. Someone standing on the drive often helps it go down, but the end caps will eventually 'clamp' beyond that... But it goes UP ok, because the force is around 3 times higher....

On to the electrical side.

'Trim' and 'tilt' are the same thing as far as the hydraulic and electrical systems are concerned. They are more a definition of the range of travel. 'Trim' is usually the lower half of the range, and 'tilt' is the upper, or as determined by the trim limit switch adjustment... (more on this later)

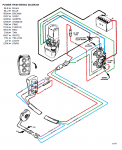

The DOWN side is easy. If single solenoid, power goes directly from the trim switch panel/button to the pump. The wires will be fairly heavy, as they are carrying full motor current. If twin solenoids, then the current from the switch/button picks the solenoid. and that switches the power to the motor... (I'll include a circuit diagram for you once I know which system you have)...

UP side is a bit more complex, as it involves a trim limit switch (or a jumper wire if the limit switch has failed and the owner hates having to use the 'TRAILER' button all the time.

)

UP is always powered through a solenoid. Power for the UP goes first to the limit switch (early model to about 1974 had the limit switch mounted below the gimbal ring upper swivel pin. Later have the hinge pin mounted 'pucks'). If the limit switch is closed (drive is in or near the DOWN position), the current then picked the UP solenoid. If the limit switch was open, or opens while the drive was going UP, as it reached the limit of 'trim', the solenoid would drop out and the motor stop. If you wish to raise the drive higher than the trim limit, the trailer button (or on the 3 button panel, the centre and top buttons pressed together) would bypass the limit switch and allow the pump to raise the drive to the top of travel...

Limit switches are know to fail, quite regularly, and as they are a PITA to replace, a lot of people just make up a short (1") jumper, with a male bullet connector on each end, and bypass the limit switch where its wires connect to the trim pump harness. Once you do that, there is no 'trim limit', the whole range, as far as the trim panel/buttons are concerned are the trim range (because the limit switch will never open)...

The trim gauge and its sender are completely separate to the trim pump harness and controls. The pump doesn't get any feedback from the gauge, at all. So the gauge and the pump are not reliant on each other to work. Each will work without the other working.

Hope this helps.....

Chris.........