Watermann

Starmada Splash of the Year 2014

- Joined

- Jan 12, 2013

- Messages

- 13,842

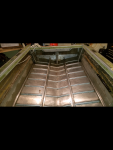

Decking, most don't use marine grade due to the cost. A good exterior grade fir plywood sealed up will last many decades if cared for properly.

A lot of the 16'rs came with the 85 Johnny, strong motors that like fuel.

You're welcome on the rivet thread, I had to do the rivets sticky as I was answering the same questions weekly. :lol:

A lot of the 16'rs came with the 85 Johnny, strong motors that like fuel.

You're welcome on the rivet thread, I had to do the rivets sticky as I was answering the same questions weekly. :lol: