Fishermark

Vice Admiral

- Joined

- Oct 19, 2003

- Messages

- 5,617

Just bought a project boat - 1985 Wellcraft 192 American. It has a Mercruiser I/O. The transom was rotted out, so I tore it down and removed the old top layer of fiberglass and rotten wood.

I have read the various posts and watched many of the videos... thanks to those who posted them, they are helpful!

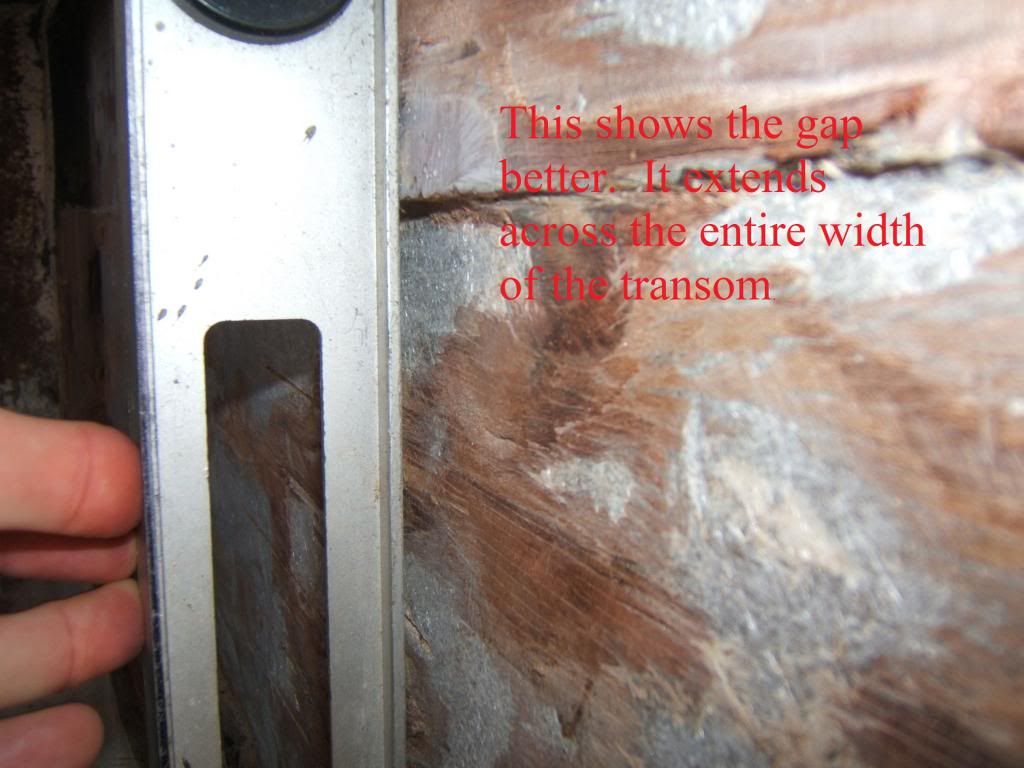

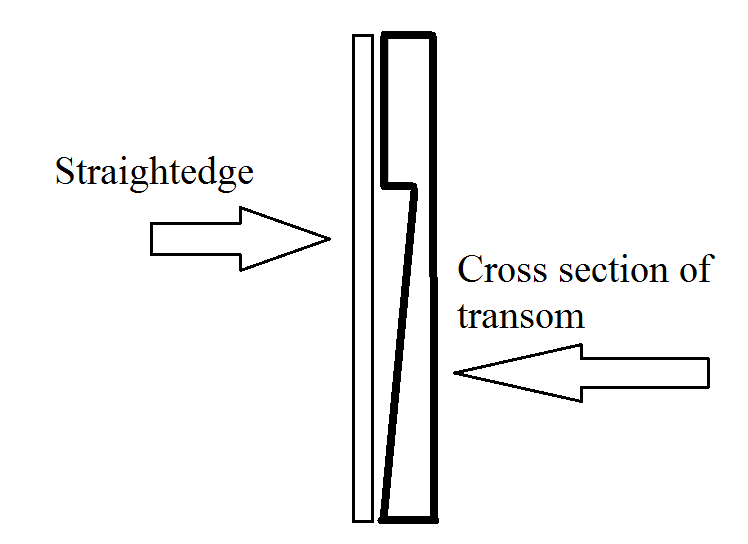

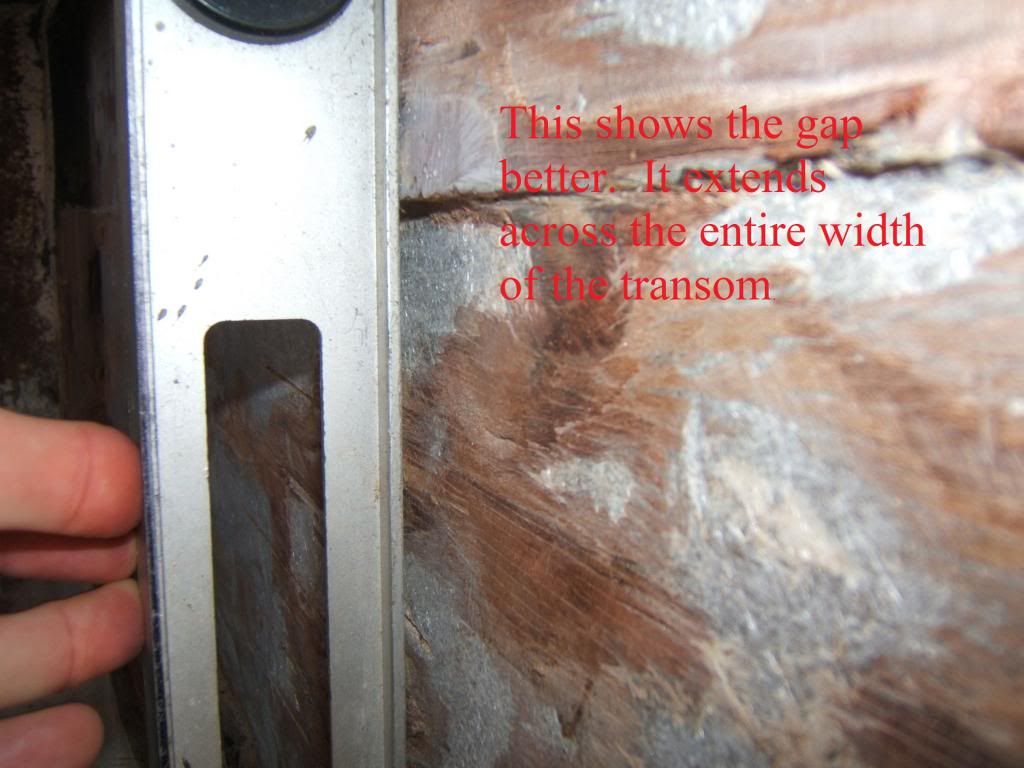

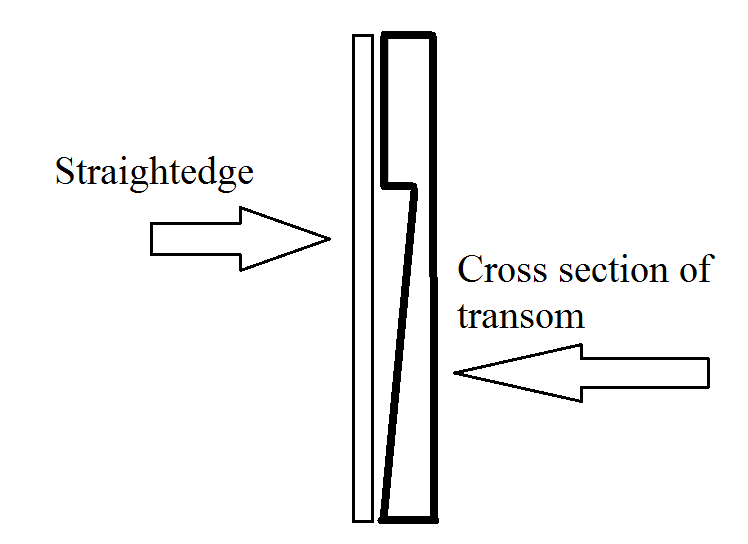

I have run into a bit of a problem, and not sure how to handle it. When I removed the old wood, I noticed that there was a big ridge on the back of the fiberglass. It looked liked they had glassed in the wood at two separate times. There is about a six inch wide section across the top of the transom that is thicker than the rest. In fact, if I take a straight edge and run it up from the bottom to the top, the top six inches is flat against the straight edge. The thickness around the keyhole also goes from thinner at the top to thicker at the bottom.

What's the best way to deal with this issue? Any thoughts? Here's a couple of pics and a drawing to show what I mean.

I have read the various posts and watched many of the videos... thanks to those who posted them, they are helpful!

I have run into a bit of a problem, and not sure how to handle it. When I removed the old wood, I noticed that there was a big ridge on the back of the fiberglass. It looked liked they had glassed in the wood at two separate times. There is about a six inch wide section across the top of the transom that is thicker than the rest. In fact, if I take a straight edge and run it up from the bottom to the top, the top six inches is flat against the straight edge. The thickness around the keyhole also goes from thinner at the top to thicker at the bottom.

What's the best way to deal with this issue? Any thoughts? Here's a couple of pics and a drawing to show what I mean.