Re: Raising the floor of the transom shower

So the marine silicone would be applied to prevent water from sitting under the poly plug? (I'm not sure how removable 5200 is, I have an old rope deck pipe that I can't remove

)

3M 4200 isn't as permanent...

But if I'm understanding glenn's plan, it sounds to me like you are too. It allows you to make a generous pour, over poured even, and contour the topside to be exactly like you want it to be, possible even removable at some point to return it to it's factory look & poor functionality.

MarineTex might be a good alternative too, just to fill in the trough. Put down on top of a sheet of waxpaper, then contour & shape the topside to fit & direct the water up to & thru the fitting. Interesting that the water sits IN the trough that was intended to help direct the water towards & thru the fitting :facepalm:

That drain goes DIRECTLY thru the hull? Not attached to a hose of any kind? And the thru hole fitting is on the SIDE of the compartment not in the REAR? If so, to some degree filling just the trough will allow the water to pool elsewhere. Are you wanting to COMPLETELY re-pitch most (all) of the compartment's bottom, to keep everything headed to the drain & have a new higher trough to direct the water out? For that, I might recommend using and epoxy that could be mixed & poured then contoured somewhat. Scuff the bottom of the bin w/ 80g or 120g, wipe down good w/ acetone & mask off your fill line, and pour epoxy up to line.

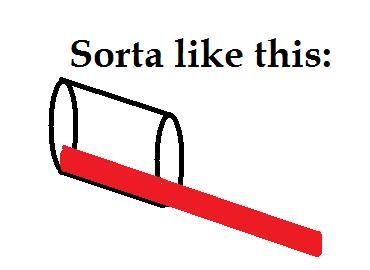

You could insert a dowel thru the drain, silicone it into the drain, to keep epoxy from making the dowel permanent and have a 3 to 4" piece stick out into the bin. To that end attach a piece of plumbing PVC @ 1.5" in diameter (about the same as your thru hull fitting's outer diameter) and have it running uphill to recreate the trough. Wrapped w/ wax paper or aluminum foil, the PVC could be removed after, and again using silicone to seal the edge where it contacts the bin's sides, keeps the PVC from becoming permanent also.

The dowel has had a recess cut along the 3-4" that protrude into the boat to maximize how close the trough comes to the thru hole.

Al that ^^^ supposes that the thru hull fitting is

angled down & out, not straight thru the hull. If it's staright, a similar plan w/ just PVC might remake the trough too.

OR:

Just tilt the boat on it's side after ever outing & shake until all the water makes it's way up & into the fitting