cyauch

Petty Officer 3rd Class

- Joined

- Jul 10, 2020

- Messages

- 91

I seriously hate having to ask this. Spent the better part of a day and a half trying to find an answer that wasn't immediately contradicted by someone else....who doesn't own, nor ever owned, an I/O  . I also feel I'm starting to believe this place is becoming my second home too.....which may not be a bad thing.

. I also feel I'm starting to believe this place is becoming my second home too.....which may not be a bad thing.

But here's the deal: I'm finally getting some sea trials out of the way in prep for the season (and some major repairs following an underwater strike). On the last trial, i noticed water weep from the Port riser to manifold area. Maybe a drop or two, but water none the less. I have a set of VP OEM gaskets on the way, but this weekend coming up is the only time I'll really have time to do more short trial runs to check other things out. I picked up circ pump gaskets and the marine shop gave me a set of Sierra manifold / riser gaskets because they kept getting wrong circ gaskets from their supplier before getting the correct VP one.

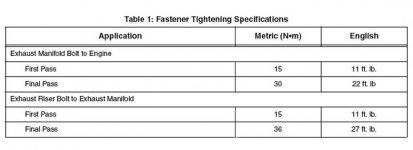

So the Sierra's are grey, seem pretty think, and appear to be a graphite type gasket. Do i use the same VP torque spec for the VP OEM's? All other threads and post on the interweb seem to dive into 'green paper gaskets are bad' and i'm dumbfounded how that even came up since that usually wasn't the OP's question anyway. But here we are.

So yea, this won't be a long term fix, but i'm nervous about what I'm gonna find since I'm sure these are the original manifolds and risers (15 years old). And yes, i will replace them asap no matter due to the issues with overheating (seems resolved but want to take it on trials and do some more tests) and condition of the RWP i just replaced. I just need this to work for this weekend only so i can check the repairs and maintenance done on other things the past few months. Then, during the two weeks that follow, tear things down, order the replacement parts, and get ready for another set of trials for those parts in 2 - 3 weeks. I just wanna order as much as i can in one shot vs order, wait, order, wait, etc.

I tried to also find a Sierra site that might help with torque specs but either i'm a loser or it doesn't exist

THanks

But here's the deal: I'm finally getting some sea trials out of the way in prep for the season (and some major repairs following an underwater strike). On the last trial, i noticed water weep from the Port riser to manifold area. Maybe a drop or two, but water none the less. I have a set of VP OEM gaskets on the way, but this weekend coming up is the only time I'll really have time to do more short trial runs to check other things out. I picked up circ pump gaskets and the marine shop gave me a set of Sierra manifold / riser gaskets because they kept getting wrong circ gaskets from their supplier before getting the correct VP one.

So the Sierra's are grey, seem pretty think, and appear to be a graphite type gasket. Do i use the same VP torque spec for the VP OEM's? All other threads and post on the interweb seem to dive into 'green paper gaskets are bad' and i'm dumbfounded how that even came up since that usually wasn't the OP's question anyway. But here we are.

So yea, this won't be a long term fix, but i'm nervous about what I'm gonna find since I'm sure these are the original manifolds and risers (15 years old). And yes, i will replace them asap no matter due to the issues with overheating (seems resolved but want to take it on trials and do some more tests) and condition of the RWP i just replaced. I just need this to work for this weekend only so i can check the repairs and maintenance done on other things the past few months. Then, during the two weeks that follow, tear things down, order the replacement parts, and get ready for another set of trials for those parts in 2 - 3 weeks. I just wanna order as much as i can in one shot vs order, wait, order, wait, etc.

I tried to also find a Sierra site that might help with torque specs but either i'm a loser or it doesn't exist

THanks