jigngrub

Fleet Admiral

- Joined

- Mar 19, 2011

- Messages

- 8,155

Re: Screwing down vinyl deck and pouring foam

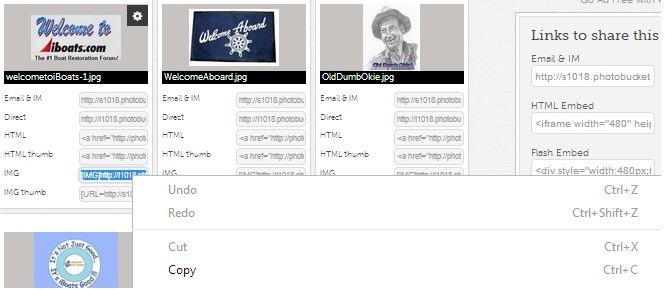

About posting the pics, click on the reply with quote button on my post with your pic in it and you will be able to see what code I copied from photobucket. You can also see how I posted it in a line by itself, don't try to post the pic code in a sentence it needs to stand alone. If you still have problems, just upload your pics to photobucket and I can post them for you until you get the hang of it.

Take some more pics of your boat when you get all the wood and foam removed so we can see exactly what you have to work with.

Electrical work isn't my forte, but you can get some good help in the electrical forum on this site right here:

Electrical, Electronics, Audio and Trolling Motors

About pouring your foam:

It's much better to pour the foam before the decking goes down, you can get a complete and void free foam filled hull that will displace any water that tries to enter and actually seal your hull in case of a breach. This can be achieved by using a sheet of cheap OSB plywood wrapped in 6 mil plastic sheeting , I'll expand on this further if you're interested.

Sealing your decking:

This is very important and the better job you do of it the longer your decking and vinyl job will last. I strongly recommend using 2 part marine grade epoxy resin for this. USComposites (google it) has a 635 thin epoxy resin that works very well for this. Most people use the 3:1 medium hardener, but if you're working in cooler temperatures you may want to go with the 4:1 fast hardener which isn't really that fast in cooler temps.

Have you checked your transom wood for rot? Now is the best time to do this since you already have the boat taken apart and it'll be much easier to do now than waiting until later and having to take your boat apart again. Some folks go ahead and change it out whether it looks like it needs it of not just for the peace of mind and so everything will be new on the boat when it's finished.

did you ever check out the vinyl job I did to my boat I posted the link to back in post #7 of this thread?

About posting the pics, click on the reply with quote button on my post with your pic in it and you will be able to see what code I copied from photobucket. You can also see how I posted it in a line by itself, don't try to post the pic code in a sentence it needs to stand alone. If you still have problems, just upload your pics to photobucket and I can post them for you until you get the hang of it.

Take some more pics of your boat when you get all the wood and foam removed so we can see exactly what you have to work with.

Electrical work isn't my forte, but you can get some good help in the electrical forum on this site right here:

Electrical, Electronics, Audio and Trolling Motors

About pouring your foam:

It's much better to pour the foam before the decking goes down, you can get a complete and void free foam filled hull that will displace any water that tries to enter and actually seal your hull in case of a breach. This can be achieved by using a sheet of cheap OSB plywood wrapped in 6 mil plastic sheeting , I'll expand on this further if you're interested.

Sealing your decking:

This is very important and the better job you do of it the longer your decking and vinyl job will last. I strongly recommend using 2 part marine grade epoxy resin for this. USComposites (google it) has a 635 thin epoxy resin that works very well for this. Most people use the 3:1 medium hardener, but if you're working in cooler temperatures you may want to go with the 4:1 fast hardener which isn't really that fast in cooler temps.

Have you checked your transom wood for rot? Now is the best time to do this since you already have the boat taken apart and it'll be much easier to do now than waiting until later and having to take your boat apart again. Some folks go ahead and change it out whether it looks like it needs it of not just for the peace of mind and so everything will be new on the boat when it's finished.

did you ever check out the vinyl job I did to my boat I posted the link to back in post #7 of this thread?