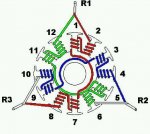

I've noticed that the after market stators seem to have some slight modifications. The one pictured below was wrapped on two extra posts whereas the OEM stator didn't have the 9th & 10th post wrapped. Also, posts 11 and 12 were the ones wrapped in a very fine gauge. I was not able to see which way they were wrapped. The red lead went to one coil and the blue lead went to the other coil. The ground lead I believe joined both coil 11 and 12 which then went to the power head. Please tell me if this seems wrong.

(Don't ask me why this replacement stator has an extra red and blue lead but no black one) :help::noidea:

I am thinking coil 11 & 12 should be wrapped CW and CCW respectively. Please correct me if this is wrong! :dejection:

Tomorrow I plan to run to the local store and get magnet wire, file the corners smooth, maybe borrow a sandblaster if I'm lucky, and then epoxy on some new insulating material on. Any thoughts on a better insulator/encapsulation? I thought gauze, but that might become flammable... as would athletic tape. The problem with Epoxy is it will allow the coils to ground if it overheats enough to melt. I've heard of using JB Weld, but then I couldn't see my coils later on. Hmmm

layball:

To anyone following me; Stator posts 11 & 12 don't have a "foot" to retain the coils, so when your plastic melts, it'll just slip right off with the plastic if melting it upside down like I did. You may want to melt it sideways so it doesn't go anywhere and you can also tug at the red/blue leads to start unwrapping it to see which direction the coils are wound. Just my 02?

If I wind tomorrow, I plan to hook up my ohm meter to the coil wire and the stator body to make sure I'm not grounding as I go.

Whether I take it or not, any and all advice is appreciated!!!