freeisforme

Petty Officer 2nd Class

- Joined

- Mar 23, 2009

- Messages

- 184

I picked up a free boat today, it appears to be a 1960 Starcraft Voyager.

It belonged to a guy that restored Corvettes, which explains the new plywood and glass deck, and what appears to be a solid transom laid up with fiberglass throughout. It was in the water when I found it and I even got to test drive it before I took it. It ran great, did nothing wrong at all. The boat is solid, handles well, and the Tohatsu motor ran flawlessly. The only issues I found at all weren't realized till I got it home and started really going over it.

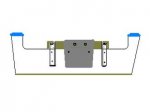

The deck is unpainted, it just had a huge piece of carpet laying over the new deck, (I tossed the carpet), the stern light is missing its lens, and the most serious, the motor is too long for the transom. It's got a 20" shaft length 40hp Tohatsu engine on a 17" tall transom. The anti ventilation plate is about 4" below the lowest part of the transom.

Keeping in mind that the boat runs and drives fine, what would you do? Raise the motor with a bracket? Find a short shaft motor? Built up the transom or shim the transom on top a bit? (Keep in mind that the motor is a clamp on style, with no bolts, so I'd only be able to add maybe a couple of inches of spacer to the top of the transom, and at that I don't like that idea much.

How strong is an all fiberglass transom? I've seen and done a few poured transoms, but this guy appears to have laid up many, many layers of mat and built up a 1.5" transom. In doing so, he's also made the top cap of the boat permanent, as the new transom and splashwell is now all one piece.

The boat uses threaded plastic through hull fittings, I was able to remove those and see that the transom is solid. I can stand on the lower unit, there's no flex at all. I'd sort of rather keep the motor weight over the transom and not add any leverage by using a bracket.

I also don't suppose I'd find any cheap running short shaft remote control motors too easily either, at least none in this size range.

As it stands right now, I have nothing invested, and it floats, runs, and has all it's paperwork.

What would be the worst case scenario if I just run it the way it is with the motor being too long?

It belonged to a guy that restored Corvettes, which explains the new plywood and glass deck, and what appears to be a solid transom laid up with fiberglass throughout. It was in the water when I found it and I even got to test drive it before I took it. It ran great, did nothing wrong at all. The boat is solid, handles well, and the Tohatsu motor ran flawlessly. The only issues I found at all weren't realized till I got it home and started really going over it.

The deck is unpainted, it just had a huge piece of carpet laying over the new deck, (I tossed the carpet), the stern light is missing its lens, and the most serious, the motor is too long for the transom. It's got a 20" shaft length 40hp Tohatsu engine on a 17" tall transom. The anti ventilation plate is about 4" below the lowest part of the transom.

Keeping in mind that the boat runs and drives fine, what would you do? Raise the motor with a bracket? Find a short shaft motor? Built up the transom or shim the transom on top a bit? (Keep in mind that the motor is a clamp on style, with no bolts, so I'd only be able to add maybe a couple of inches of spacer to the top of the transom, and at that I don't like that idea much.

How strong is an all fiberglass transom? I've seen and done a few poured transoms, but this guy appears to have laid up many, many layers of mat and built up a 1.5" transom. In doing so, he's also made the top cap of the boat permanent, as the new transom and splashwell is now all one piece.

The boat uses threaded plastic through hull fittings, I was able to remove those and see that the transom is solid. I can stand on the lower unit, there's no flex at all. I'd sort of rather keep the motor weight over the transom and not add any leverage by using a bracket.

I also don't suppose I'd find any cheap running short shaft remote control motors too easily either, at least none in this size range.

As it stands right now, I have nothing invested, and it floats, runs, and has all it's paperwork.

What would be the worst case scenario if I just run it the way it is with the motor being too long?