Hi everyone,

I have been a lurker on this website for a few months now (since I got an old outboard motor), but I have never had the need to post anything. It seems like there are tons of very knowledgeable people here, and I would really appreciate any help I can get.

I picked up a 1963 Johnson FD-17 (18hp) engine from a family friend, and he says it has been sitting in his barn for about 20 years now. He also said that it has very low hours on it, and ran perfectly when he put it up. So after reading through tons of posts in the forums, I decided to get a carb kit, ignition tune-up kit, coils, plug wires, spark plugs, and a thermostat from NAPA. I rebuilt the carb (it was surprisingly clean, but the throttle valve was seized), replaced the thermostat, and went through the whole ignition system (because one of the plugs wasn't firing when I got it, even with new plugs). After I assembled everything yesterday, I checked to make sure it had spark, and both plugs had a nice blue spark. So I put them back in and tried pulling it a dozen times, but nothing happened. After an hour of troubleshooting fuel and air, I pulled the plugs again and found that they were no longer getting spark. I have gone through the whole ignition system again and have found nothing wrong as far as I can tell. Does anyone have any ideas?

Some things I checked/don't understand:

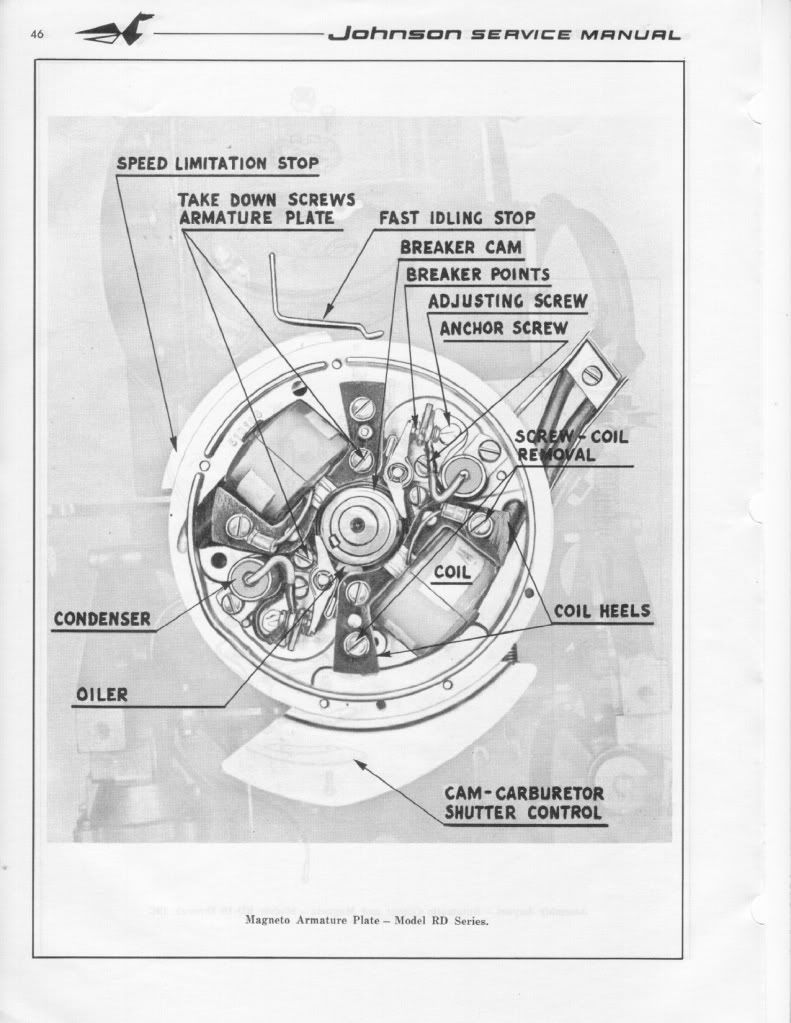

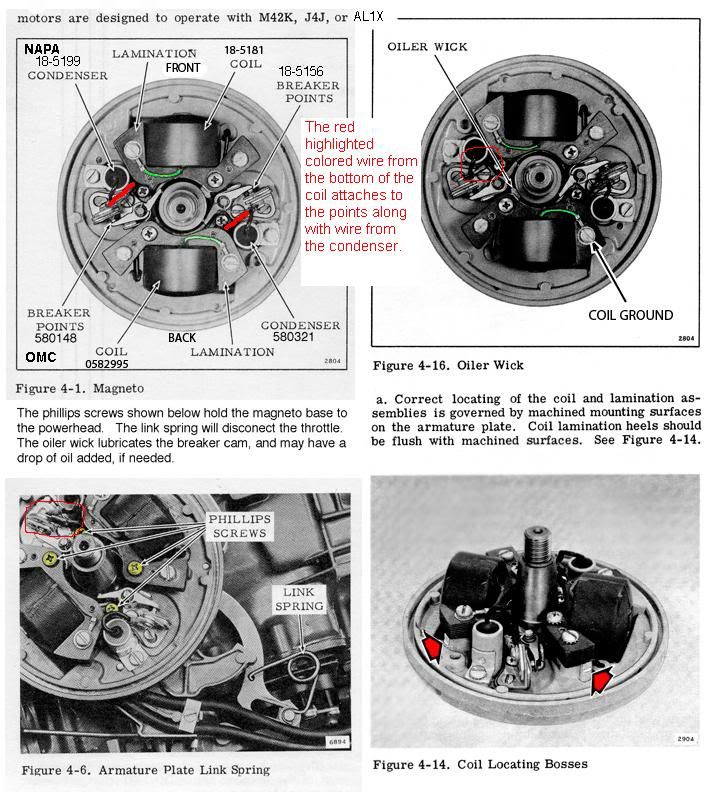

-coils are flush with the machined edges of the timing plate

-tested resistance in primary and secondary coils, both look good (on both coils)

-points are clean

-Am I turning the flywheel fast enough for spark? Is there a minimum speed to get a spark?

-What is the white wire/hose coming out from right under the timing plate and going into the base of the engine?

-What are the wires coming out of the points bases and going to my keyswitch outlet? (one from each point base)

-Does a keyswitch need to be plugged in for the ignition to work? (I don't think so, because I saw spark before)

Sorry for the long post, but I wanted to give as much detail as possible. Thanks for any input you can offer.

-weezy

I have been a lurker on this website for a few months now (since I got an old outboard motor), but I have never had the need to post anything. It seems like there are tons of very knowledgeable people here, and I would really appreciate any help I can get.

I picked up a 1963 Johnson FD-17 (18hp) engine from a family friend, and he says it has been sitting in his barn for about 20 years now. He also said that it has very low hours on it, and ran perfectly when he put it up. So after reading through tons of posts in the forums, I decided to get a carb kit, ignition tune-up kit, coils, plug wires, spark plugs, and a thermostat from NAPA. I rebuilt the carb (it was surprisingly clean, but the throttle valve was seized), replaced the thermostat, and went through the whole ignition system (because one of the plugs wasn't firing when I got it, even with new plugs). After I assembled everything yesterday, I checked to make sure it had spark, and both plugs had a nice blue spark. So I put them back in and tried pulling it a dozen times, but nothing happened. After an hour of troubleshooting fuel and air, I pulled the plugs again and found that they were no longer getting spark. I have gone through the whole ignition system again and have found nothing wrong as far as I can tell. Does anyone have any ideas?

Some things I checked/don't understand:

-coils are flush with the machined edges of the timing plate

-tested resistance in primary and secondary coils, both look good (on both coils)

-points are clean

-Am I turning the flywheel fast enough for spark? Is there a minimum speed to get a spark?

-What is the white wire/hose coming out from right under the timing plate and going into the base of the engine?

-What are the wires coming out of the points bases and going to my keyswitch outlet? (one from each point base)

-Does a keyswitch need to be plugged in for the ignition to work? (I don't think so, because I saw spark before)

Sorry for the long post, but I wanted to give as much detail as possible. Thanks for any input you can offer.

-weezy