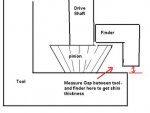

I'm using the GLM 90330 and 90335 shimming tools to determine the proper amount of shims to use on my 1988 V6 gearcase. At one end of the tool is a spring loaded plunger that the end of the driveshaft goes on. It appears that the purpose of this is to push the driveshaft, driveshaft bearing,and thrust washer against the driveshaft bearing cover that has been bolted to the other end of the tool. The instructions show the tool being used in the upright position, with the plunger at the bottom,but there is no way that the spring tension will be enough to press the thrust washer firmly against the driveshaft bearing housing. Even if I lay it horizontally it doesn't press it firmly against the bearing housing.

I'm thinking that I should invert the tool so that the weight of the driveshaft presses the bearing and thrust washer against the bearing housing and then use shims to determine the gap between the 90330 and 90335 tools.

When I use this method, I came up with .010" shims, which seems reasonable.

The old pinion gear also had .010" shims

Am I doing this right?

When the driveshaft is in the vertical position, with the plunger at the bottom, like they show in the insructions, the weight of the driveshaft causes the pinion gear to sit on the tool, with virtually no gap.

Here's a link to the instructions they send with the tool.

http://bpi.ebasicpower.com/downloads/GLM90330inst.pdf

Thanks.

Edit:

OK. I finally got the info I needed, so I can save everyone the pain of reading this entire thread. On the bottom of the tool is a large threaded plug that holds the spring and plunger in place. I needed to turn the plug in quite a bit to get enough spring pressure to push the driveshaft up, so thrust washer was pressed against the bearing housing. I don't know if they ship it that way so the spring doesn't get weak, if it sits for a long period of time, or it was just overlooked when it was assembled. In any case, there is no mention of this in the instructions. Inverting the tool will give the same result but is more difficult to do, because the tool will not sit flat on the workbench when it is inverted.

I'm thinking that I should invert the tool so that the weight of the driveshaft presses the bearing and thrust washer against the bearing housing and then use shims to determine the gap between the 90330 and 90335 tools.

When I use this method, I came up with .010" shims, which seems reasonable.

The old pinion gear also had .010" shims

Am I doing this right?

When the driveshaft is in the vertical position, with the plunger at the bottom, like they show in the insructions, the weight of the driveshaft causes the pinion gear to sit on the tool, with virtually no gap.

Here's a link to the instructions they send with the tool.

http://bpi.ebasicpower.com/downloads/GLM90330inst.pdf

Thanks.

Edit:

OK. I finally got the info I needed, so I can save everyone the pain of reading this entire thread. On the bottom of the tool is a large threaded plug that holds the spring and plunger in place. I needed to turn the plug in quite a bit to get enough spring pressure to push the driveshaft up, so thrust washer was pressed against the bearing housing. I don't know if they ship it that way so the spring doesn't get weak, if it sits for a long period of time, or it was just overlooked when it was assembled. In any case, there is no mention of this in the instructions. Inverting the tool will give the same result but is more difficult to do, because the tool will not sit flat on the workbench when it is inverted.