View attachment 176949View attachment 176950View attachment 176951

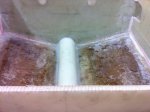

Major milestone out of the way. All stringers and bulkheads coved and glassed.

It took 8hrs over two nights to get it all down wet on wet.

Day time temps are 34 degree Celsius at the moment. Impossible to get a batch of resin to stay good in the pot.

Floor skin was trialled in position and there was minimal flex between stringers with my 90kg standing on it.

Max flex will be on firm land. When in the water this will be less.

A quick clean up of the bilge drains tomorrow then it's onto floor skins tomorrow night.

Seat boxes are glued together and are ready for interior glass.

Looking forward to testing my new flooring grip. A water based paint product called tredgrip. Oz product.

No primer needed straight onto fibreglass. Tested on some scrap and was difficult to remove after 6hrs let alone the 72 hrs recommended.

That is all for now. 5 days until deadline and still a fit out to be completed.