Yes, thank you! I'll worry about the other spot to repair later.

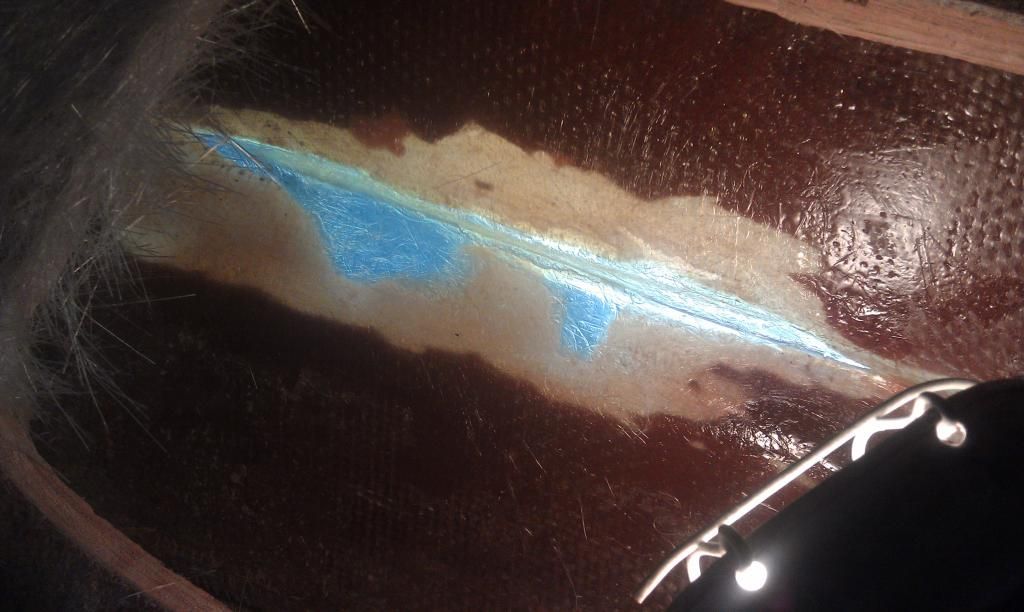

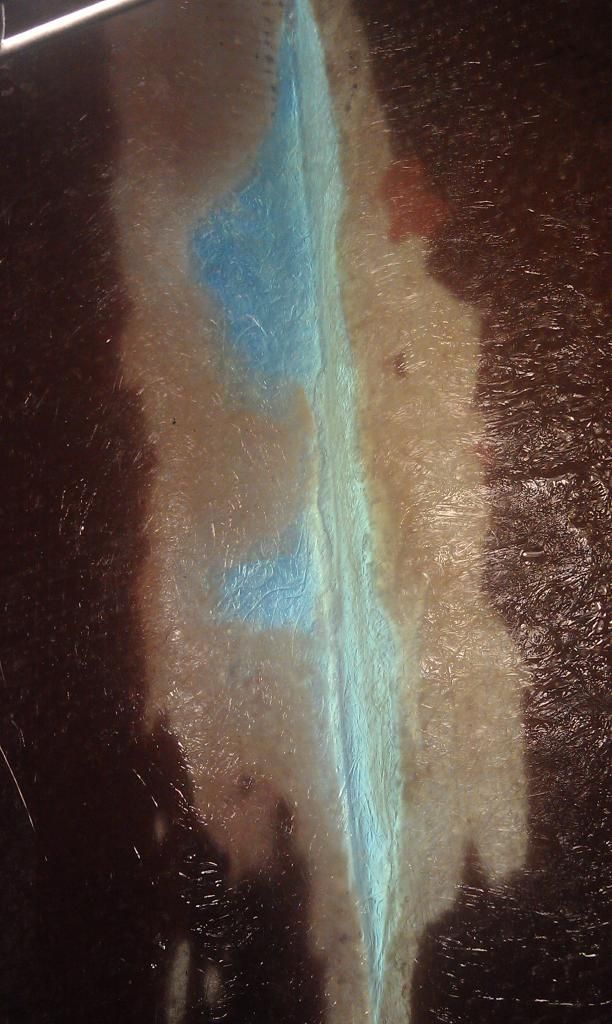

I'm almost done sanding in the other compartment so I can adequately tab the other side of the bulkhead. It looks like there's crack in the bulkhead wood but I tried reaching in there and seeing if the wood is damaged or anything and it feels strong. That crack looking thing is not on the other side, I'm really not sure what is it but it doesn't concern me. I will be filleting and glassing both sides.

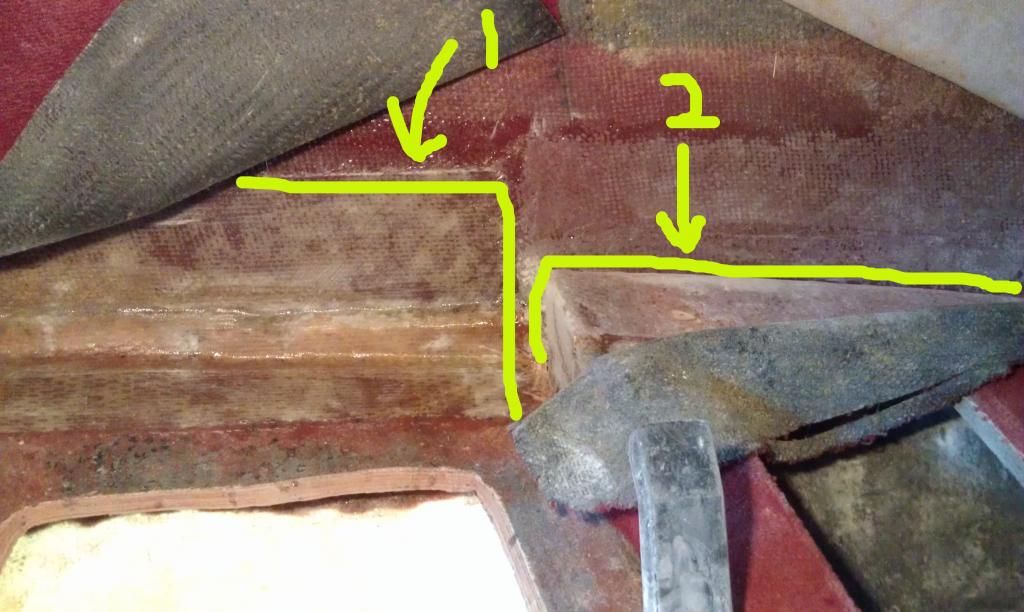

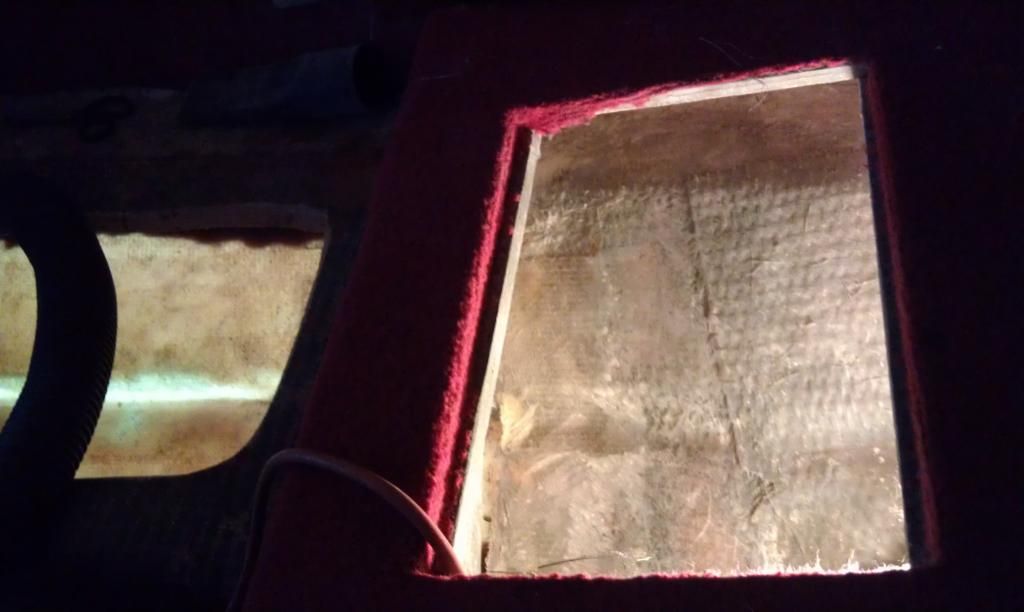

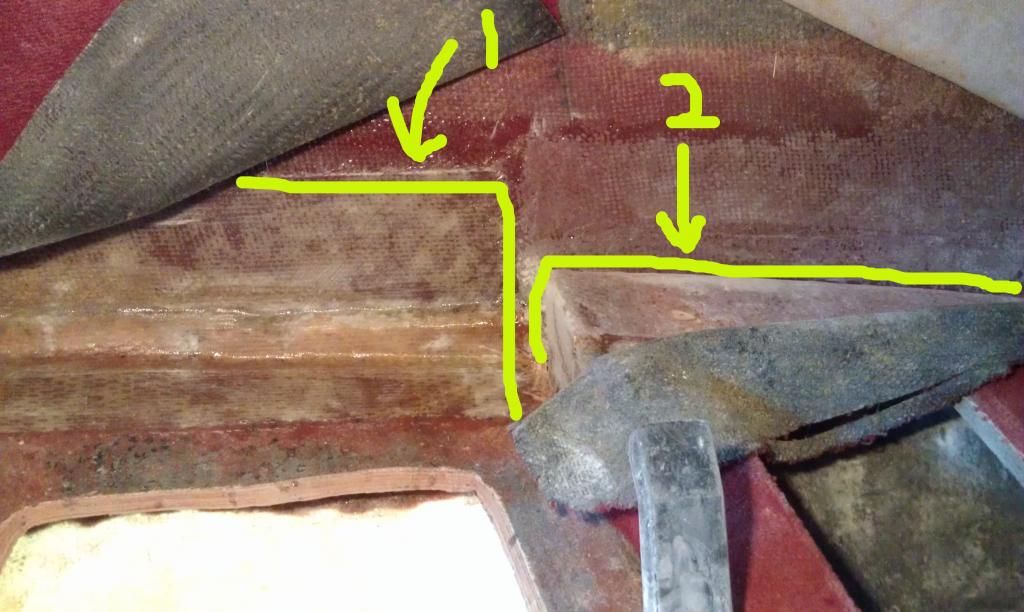

SO while I'm sanding away at the compartment forward of my hull repair, I see more things that need fixing. #1 is where I attempted to tab the cabin floor to the hull, It looks like garbage to me now and I am wondering if I should rip it off and re-do it? I tried prying at it and it seems to hold strong. That brings me to #2 which I also tried to tab, that didn't work so well and I ripped it off and sanded it down. I attempted to tab these when I was trying to fix the second time it cracked, before all the proper repairs I'm doing now.

Anyway, the outlined area of #2 was only tabbed to the hull, even though there's a big gap from the wood to the hull. Is that an area that I can fill with PB? I would like it to be rigid but if there's a good reason it wasn't filleted in the first place I will not do it.