so I recently repowered my 2004 sea ray 215 with a remanufactured long block. The motor is a 5.0 MPi

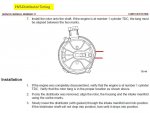

The engine is back in the boat and complete. I tried starting today and it wouldn’t go so come to find out I had the distributor 180 degrees off. After I adjusted to rotor to the number 1 cylinder at top dead center and it still won’t start and the spark is intermittent/weak it seems.

Where should I check next? checked fuel it’s getting fuel.

so now it just cranks and seems like the timing is on. But it did also act up and kinda hanging up during a crank once or twice like timing? Not advanced but the other way?

when the rotor comes to the number 1 cylinder that’s when Number is building compression does that for sure mean I’m good with the distributor? And the computer does the rest?

not sure if a timing light is needed here? Doesn’t seem like there is an adjustment to me.

Also so on the distributor there is a plug hook up but there wasn’t a connector to hook in. Someone said this plug wasn’t used until 2006?

Any help here would would be great

thanks

The engine is back in the boat and complete. I tried starting today and it wouldn’t go so come to find out I had the distributor 180 degrees off. After I adjusted to rotor to the number 1 cylinder at top dead center and it still won’t start and the spark is intermittent/weak it seems.

Where should I check next? checked fuel it’s getting fuel.

so now it just cranks and seems like the timing is on. But it did also act up and kinda hanging up during a crank once or twice like timing? Not advanced but the other way?

when the rotor comes to the number 1 cylinder that’s when Number is building compression does that for sure mean I’m good with the distributor? And the computer does the rest?

not sure if a timing light is needed here? Doesn’t seem like there is an adjustment to me.

Also so on the distributor there is a plug hook up but there wasn’t a connector to hook in. Someone said this plug wasn’t used until 2006?

Any help here would would be great

thanks