Re: stringer fiberglassing and waterproofing

This sounds like a prime example of why some of us use better wood and Proper Prep ( resin coating and resanding ) before lams go on.

As a DIYer .. you can get away with doing things two times. In the shop that kinda thing could cost us Hundreds of dollars in time alone ( remember we work at 90-100 bucks an hour .. )

I hope this helps some of Iboat members understand why Pros buy only the best of the best in materials. Very expensive we know .. but materials is only about 20% of our labor cost.

Time is money for us.

Scott .. your capping glass plan works very well in a multitude of applications. Instead of letting it set up completely though .. you could wait at Just the right gel moment where you can zip the edges right off with a fresh utility knife in about 60 seconds

.

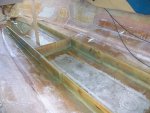

Steve .. No matter how hard you try you will get air bubbles on the caps of the stringers if the cut has Voids in it or if its not properly prepped with resin coatings.

Lets say your using CDX or something NON MG ply. You can have the risk of exposing voids in the wood when cut. Now if your cut exposed a void your going to need to fill it with some bondo or some filler ( does not matter what kinda of filler ) to fill those voids. If you dont you Will not be able to do a solid air-free lam on your wrap.

Bottom line is Do not start your lams until the Wood is Prepped properly. Some Plywood requires More prep then others. You can base the amount of prep based on how expensive the ply is. MG requires less prep and materials then CDX per say.

Hope this helps ..

YD.