- Joined

- Jul 23, 2011

- Messages

- 52,097

@brian3127

to run the motor outside the boat with or without the harness (which was covered before by Bondo, AD, Chris, Scott)

hook up the garden hose to the thermostat housing

hook up fuel tank to the fuel pump

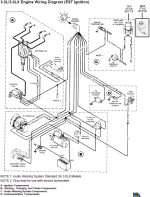

wire the block to the battery - using a 4 gauge or larger cable

wire the starter B terminal to the battery +using a 4-gauge or larger cable

run a 16 gauge wire from the battery + to the coil + (you are now "hot wired" that is also where the term came from)

turn on the water

then take a short piece of 16 gauge wire and touch the B terminal and the S terminal on the starter (or use a screw driver) and your motor is now cranking. once it runs, remove the wire or screw driver.

to shut off, remove the wire from the battery to the coil.

to run the motor outside the boat with or without the harness (which was covered before by Bondo, AD, Chris, Scott)

hook up the garden hose to the thermostat housing

hook up fuel tank to the fuel pump

wire the block to the battery - using a 4 gauge or larger cable

wire the starter B terminal to the battery +using a 4-gauge or larger cable

run a 16 gauge wire from the battery + to the coil + (you are now "hot wired" that is also where the term came from)

turn on the water

then take a short piece of 16 gauge wire and touch the B terminal and the S terminal on the starter (or use a screw driver) and your motor is now cranking. once it runs, remove the wire or screw driver.

to shut off, remove the wire from the battery to the coil.