mwe-maxxowner

Master Chief Petty Officer

- Joined

- Jun 20, 2012

- Messages

- 825

Re: dixie hustler "deck job" (turned full rebuild)

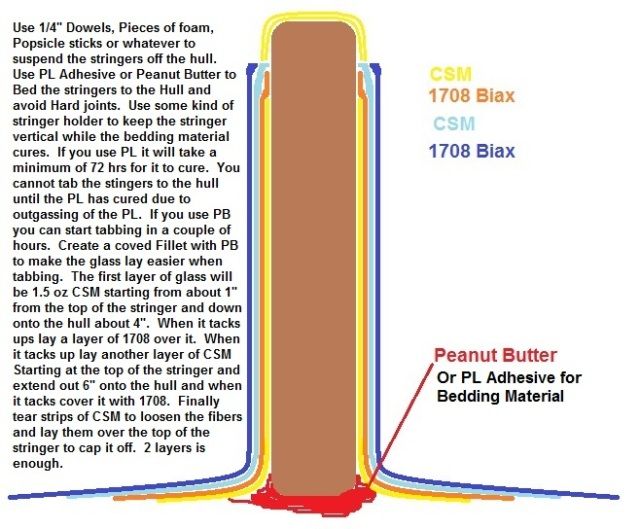

I want to build the center stringer section all together, then attach it to the hull and glass it in. Are there any reasons I shouldn't do it this way and should put it in piece by piece?

I want to build the center stringer section all together, then attach it to the hull and glass it in. Are there any reasons I shouldn't do it this way and should put it in piece by piece?