I got out there early this AM to check the glass/resin. It cured OK.

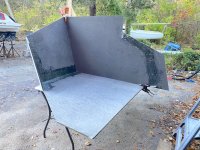

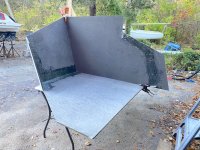

Here is a pic of the 4 pieces of the contact area set in place and glassed at the edges/corners.

.

I used some cardboard on the transom as a 'spacer' to mimic the fiberglass thickness, then stuck the Coosa pieces to the cardboard. It seemed to work OK. I figured the cardboard was about 3/32", which would give me about 0.09" thickness offset to account for the glassing on the transom-mating side.

With a couple of swift tugs, the thing came off. Looks OK . . . probably as good as I was going to get.

.

.

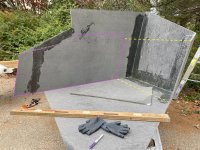

I put the center support in place to see how well it matched the transom angle . . . Looks good!

.

No gaps . . .

.

.

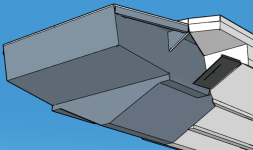

I need to check some dimensions and then start putting the rest of it together. The transom 'plate' and the top plate are going to have some decent-sized cut-outs for fabrication and assembly access. I'm thinking that I won't make the cut-outs until much of the box structure is fastened together.