COURT JESTER

Petty Officer 2nd Class

- Joined

- May 9, 2017

- Messages

- 119

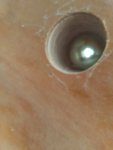

I don't have many pictures of me laminating. I never worked with epoxy resin but I worked with polyester resin for many years. So I laid half the boat up with 17 oz and that bucket is there to clean the amine blush left behind after it cured. I have now have 3 layers of 17oz on the whole hull bottom. I originally was going to put 2 layers of 17oz but I want this boat light and strong. I never want to do this to this boat again. My intention is to keep it for a very long time. That's why I switched to epoxy and want to make an epoxy boat. One good benefit is it doesn't have a strong odor. The other picture is of the hole I patched with 2 layers of 17oz before covering with the 3 layers of 17oz.